An important tool in the Aeon arsenal is environmental monitoring, which allows for the measurement of temperature and humidity within a particular environment over time. Environmental monitoring is central to understanding conditions that materials are experiencing. After data is collected, it is possible to use that baseline data to identify changes to normal conditions. Tracking these changes is useful because it can sometimes establish a correlation between changes to the environment and changes exhibited by materials. Other techniques—such as visual inspection or thermal imaging— can then be used to find the cause of materials changes.

In order for environmental monitoring to be effective, multiple reading locations need to be used throughout each site. In ongoing projects, Aeon has deployed nineteen remote data loggers, including three infrared surface sensors, fifteen ambient air sensors, and one VOC sensor. Equipment is placed at locations away from sunlight and radiant heat to gather a true ambient reading. Additionally, the longer the period during which data is gathered, the lower the margin for error.

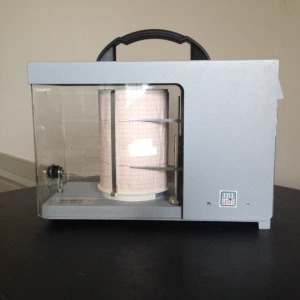

Environmental monitoring continues to evolve, and modern remote monitoring offers several advantages over earlier techniques, such as hygrothermograph. The data produced by remote monitoring is both more accurate and easier to obtain, as there is no need to check equipment in person. This lowers the cost of labor and is especially beneficial if monitoring equipment is located in places that are not easy to reach, such as around the perimeter of a dome. Depending on the data logger used, gathered information can be accessed through Wi-Fi, Bluetooth, or cellular network.

On the other hand, remote monitoring does not eliminate labor costs since data loggers still need to be placed and data interpreted. If using a cellular network, it is also dependent on cellular service providers. Aeon has been using Onset’s U-30 system, which relied on 2G networks that are being phased out, necessitating the purchase of new equipment. Keeping up with environmental monitoring technology is therefore a constant process.